Product Details

Power Grid Quadruped Inspection Robot

Intelligent robot technology and smart grid have become the forefront of technological innovation. Although the intelligent inspection technology has been applied in the power industry, the existing wheeled robot inspection technology still faces the limitations of complex terrain adaptation and cannot meet the needs of the whole station inspection coverage.

Key words:

Power Grid Quadruped Inspection Robot

Category:

E-mail:

Details

Revolution in Power Operations: How DKNC Quadruped Robots Redefine Energy Security

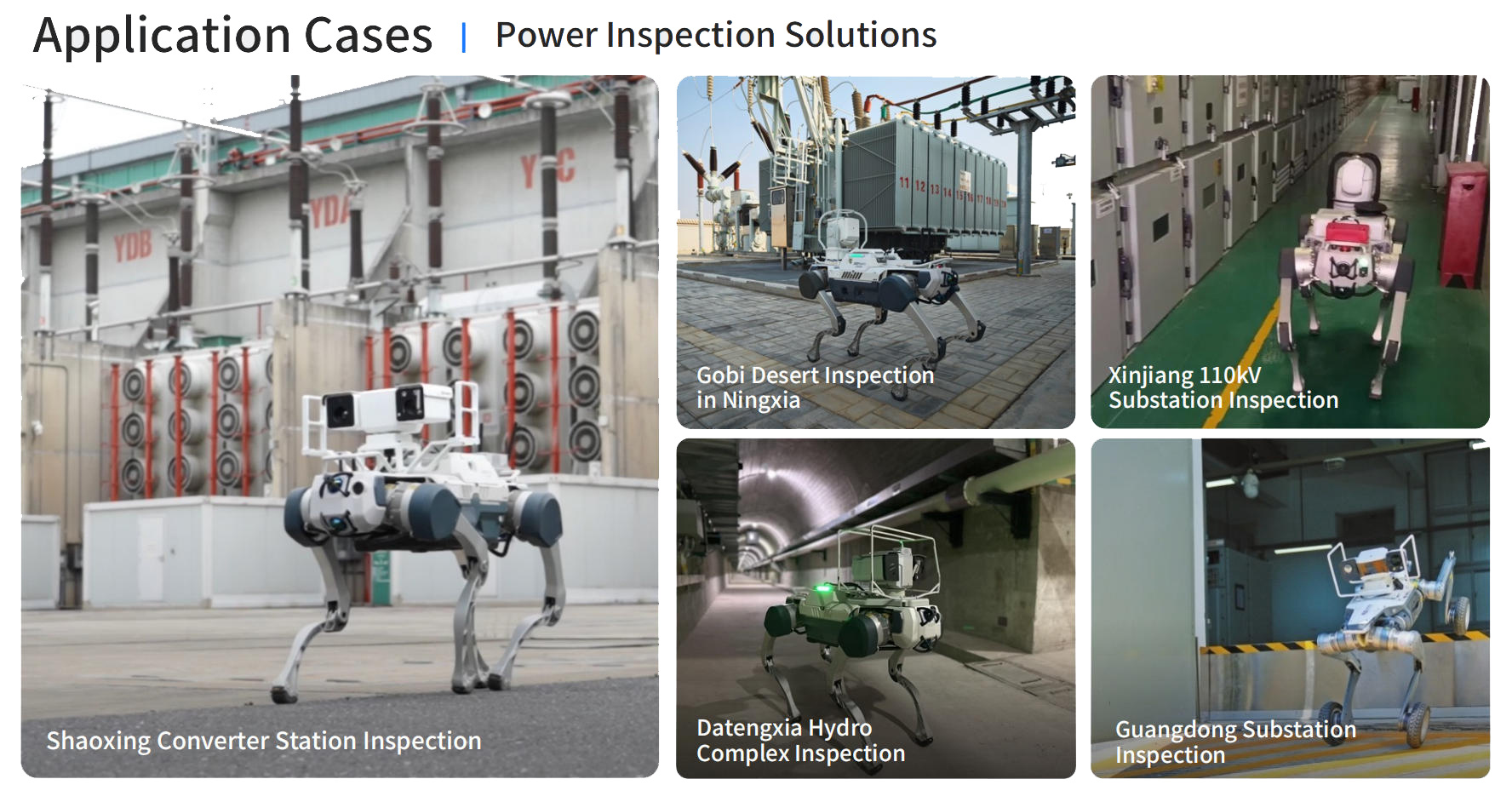

In high-risk, high-difficulty, and high-frequency power scenarios—such as high-voltage substations, underground cable tunnels, and Gobi transmission corridors—traditional manual inspections face three critical challenges: high personnel safety risks (electrocution, suffocation, falls), low operational efficiency (night/extreme weather gaps), and surging hidden costs (fault escalation due to missed defects). DKNC, driven by Embodied Intelligence, deploys its Jueying X30 and Wildcat M20 quadruped robot solutions, becoming a strategic partner for industry leaders like State Grid and China Southern Power Grid in intelligent transformation.

1.Deep Scenario Adaptation: Solving the "Impossible Triangle" of Power Operations

Pain Points | CloudDeep Solutions | Verified Outcomes |

Extreme Environment Operation | ▶ IP65 protection + Wide-temperature operation (-20°C~55°C) | 8-hour continuous inspection in sandstorms at Xinjiang 110kV substation |

Complex Terrain Traversal | ▶ 30° slope climbing + 15cm step crossing | 100% terrain coverage at Guangdong substation |

Prolonged Continuous Inspection | ▶ Hot-swap battery (3-min replacement) | Day-night shift rotation at Zhejiang converter station |

Technical Breakthrough:

Wildcat M20’s "Auto-Switch Wheel-Leg Mechanism"—30km/h wheeled cruising on flat ground (4× efficiency boost), auto-switching to legged mode for obstacles—solves the "last-meter" inspection challenge in dense substation areas.

2.Intelligent Diagnosis: From "Visibility" to "Understanding"

Multimodal Perception Fusion

Infrared Thermal Imaging: 0.1°C sensitivity, pinpointing overheating risks (e.g., faulty disconnectors)

LiDAR SLAM: Centimeter-accurate point cloud modeling, real-time 3D digital twin for tunnels

Acoustic Diagnostics: ≥95% accuracy in identifying mechanical faults (e.g., transformer abnormal noise)

Autonomous Decision Engine

Emergency Response: Auto-approach for multi-angle imaging & alerts upon detecting smoke/oil leaks

Adaptive Navigation: <5cm positioning error under strong EMI (±800kV converter stations)

Swarm Collaboration: "Multi-dog per station" task system boosts global efficiency by 80%

3.Industry-Leading Cases: Defining New Standards for Power Inspection

3.1. Global Benchmark: Singapore Power Grid (SP Group)

Challenge: Narrow underground tunnels (<1m diameter), methane accumulation, high-risk manual entry

Solution: Explosion-proof gas sensors on customized Jueying X30 "SPock" for hazardous zones

Results: ▶ 480 saved labor-hours/year ◉ Automated digital work orders ◉ SP Group global certification

3.2. Domestic Breakthrough: ±800kV UHV Converter Station

Milestone: 1,000+ hours failure-free operation under intense electromagnetic fields

Smart Management: Cloud platform monitors real-time battery, tasks, and device health

Economic Impact: 6 high-risk positions reduced per station, 40% lower O&M costs

3.3. Frontier Mission: Xinjiang Unmanned Transmission Inspection

Operated at -25°C; laser SLAM navigation without GPS

Detected tower foundation tilt buried by sandstorms, preventing cross-regional blackouts

Market Leadership:

85% domestic power inspection share,

covering 500+ substations across 34 provinces,

12% higher fault-alert accuracy than industry average.

3.4.Technological Moat: Self-Developed "China Core"

Joint Modules: In-house high-torque-density motors (300N·m peak) + precision harmonic reducers (>100k-hour lifespan)

Algorithm Core:

Motion Control: Hierarchical reinforcement learning for dynamic gait optimization (<10ms latency)

Embodied Intelligence: Auto-generates new skills for environmental changes (e.g., anti-slip gaits on ice)

Standard Authority: Led 8 national standards (e.g., Inspection Robot Safety Requirements), 100+ patents

4. Future Evolution: From "Labor Replacement" to "Ecosystem Transformation"

Wildcat M20 2025 Upgrades:

Live-Work Operations: Robotic arm modules for insulator cleaning/bolt tightening

Predictive Maintenance: AI forecasts equipment degradation 14 days ahead

Energy IoT Node: 5G-enabled real-time data sync with grid dispatch systems

Industry Forecast: With NEA’s Smart Inspection Robot Guidelines, DKNC will shift power O&M from "periodic maintenance" to "all-condition monitoring," projected to reduce 60% accidents and 50% costs by 2030.

Send Inquiry

We will contact you within one working day. Please pay attention to your email.

Related Solutions

A novel parallel reactor is connected to the power system in a parallel configuration to compensate for capacitive reactive power in the transmission and distribution system.

Intelligent Transformer Breather( ITB)

An IoT-enabled transformer accessory dedicated to digitalized monitoring of respiration metrics (flow rate, temperature, humidity) for large power transformers. It eliminates manual maintenance through active silica gel regeneration and delivers real-time insulation condition analytics.

Our wave trap surgically remove specific interference frequencies (e.g., 50/60Hz hum, RF noise). Featuring high Q factor and steep attenuation, they eliminate unwanted signals while protecting adjacent frequencies—boosting SNR, dynamic range, and system reliability in audio processing, RF design, and test & measurement applications.