Product Details

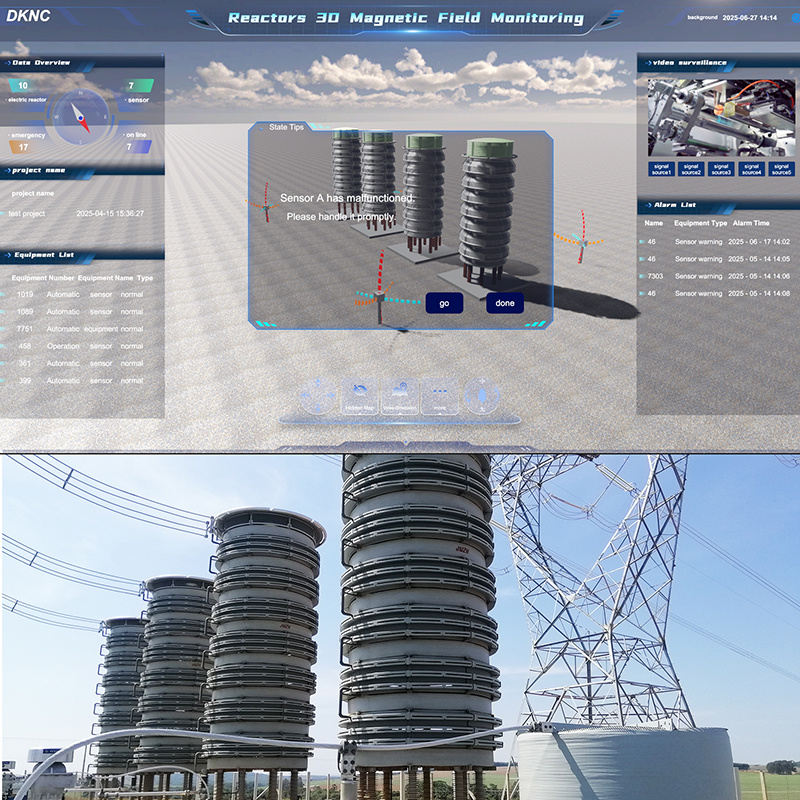

Reactors 3D Magnetic Fleld Monitoring System

DKNC Reactor Monitoring System redefines magnetic field monitoring standards through a "Sense-Analyze-Decide-Act" closed-loop architecture, delivering critical support for global power grid stability.

Key words:

Reactors 3D Magnetic Fleld Monitoring System

E-mail:

Details

Three-Dimensional Magnetic Field Monitoring System and Online Monitoring Platform: Redefining Health Management for Electrical Equipment

In the field of electrical equipment safety operations and maintenance, traditional monitoring methods often suffer from limitations such as single-dimensional analysis, delayed response, and complex deployment. The Three-Dimensional Magnetic Field Monitoring System and Online Monitoring Platform developed by DKNC integrates cutting-edge sensing technology and intelligent analytics to deliver a comprehensive, high-precision health management solution for global electrical equipment.

Core Product Value: Perception-Analysis-Decision Closed Loop

The product establishes a "Perception-Analysis-Decision-Execution" closed-loop framework. Through the synergy of non-invasive 3D magnetic field monitoring devices and a global online monitoring platform, it enables real-time monitoring, intelligent early warning, and full lifecycle management of magnetic field conditions for critical equipment like reactors. This significantly enhances operational efficiency and safety.

1. 3D Magnetic Field Detection Device: High-Precision Sensing, Leaving No Fault Undetected

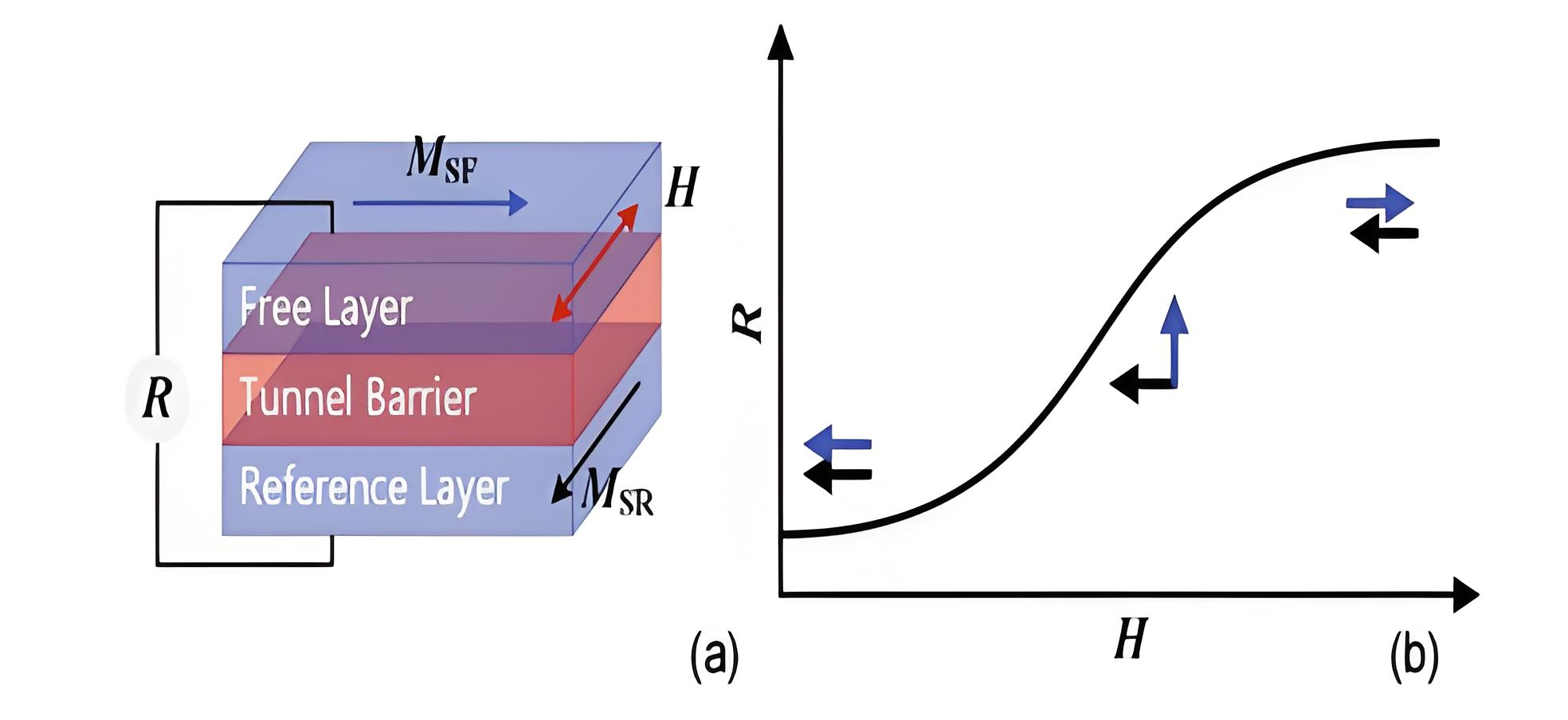

1.1 Three-Dimensional Sensing

Utilizes highly sensitive Giant Magnetoresistance (GMR) technology with integrated X/Y/Z triaxial orthogonal sensors (spacing ≤3mm) to accurately capture spatial magnetic field vector data:

Accuracy: ±0.5% FS, 16-bit resolution

Supports full-frequency signals (50Hz–250Hz), covering steady-state power frequency and transient harmonics.

1.2 Millisecond-Level Fault Detection

Employs moving central average algorithm and confidence interval warnings (t-test) to calculate magnetic field deviation index (D) in real time.

Triggers alerts when D > 5S, identifying early-stage inter-turn short circuits (≤5 turns) with response time <1 second.

1.3 Industrial-Grade Reliability

2000 samples/sec high-speed sampling (hardware timer Tim3).

LoRa wireless transmission of 12 key parameters (max magnetic field, variance, etc.), supporting hexadecimal/text dual formats.

Resists strong electromagnetic interference (stable operation at -20°C to 65°C). Live installation requires no equipment modification, tripling deployment efficiency.

2. Global Online Monitoring Platform: Intelligent Operations Hub

2.1 3D Visualized Monitoring

Dynamically renders 3D magnetic field cloud maps of reactors, supporting rotation, sectioning, and anomaly highlighting.

Synchronously displays real-time X/Y/Z-axis waveforms, historical trends, and alarm thresholds, enabling data drilling analysis.

2.2 Multi-Protocol Global Access

Compatible with MQTT/HTTP/Modbus protocols, achieving second-level data synchronization and supporting cluster management for tens of thousands of devices.

2.3 Smart Alerts & Remote Control

Customizable multi-level alarms (magnetic field intensity/mutation rate thresholds) trigger SMS/email/light-sound notifications.

Remote adjustment of sampling frequency, alarm rules, and LoRa channel parameters; supports batch command deployment.

2.4 Full Lifecycle Management

Stores equipment records (location, maintenance logs) and >1 year of historical data (time-series database archiving).

Cloud-based big data analytics provide predictive maintenance recommendations, reducing fault localization time from 4 hours to 15 minutes.

3.System Synergy: Edge-Cloud Integration, Global Control

Global Device Mapping: Geolocates equipment, monitors real-time status/alarm statistics, and adapts to multi-time-zone grid demands.

Edge-Cloud Efficiency: On-device signal filtering/feature extraction + cloud-based deep analysis (e.g., lifespan prediction), boosting data processing efficiency by 50%.

Enterprise Security: AES encrypted transmission + role-based access control (super admins/operators).

4.Applications & Innovative Value

Key Scenarios: Magnetic field health management for substation dry-type reactors, transmission line equipment, and industrial large-scale inductive devices.

Breakthroughs:

✅ World’s first 3D magnetic field modeling for precise spatial distribution mapping.

✅ Edge-cloud architecture balancing real-time performance and computational efficiency.

✅ Non-invasive deployment across global voltage classes, eliminating downtime for retrofits.

Redefining Industry Standards

Anchored in "magnetic field perception," this product bridges the entire chain from data acquisition to intelligent decision-making, delivering critical technical support for secure and stable power systems. Whether capturing microsecond-level magnetic distortions or enabling centralized global device management, the 3D Magnetic Field Monitoring System pioneers a new era of high-dimensional intelligence in electrical equipment health management.

Send Inquiry

We will contact you within one working day. Please pay attention to your email.

Related Solutions

A novel parallel reactor is connected to the power system in a parallel configuration to compensate for capacitive reactive power in the transmission and distribution system.

Intelligent Transformer Breather( ITB)

An IoT-enabled transformer accessory dedicated to digitalized monitoring of respiration metrics (flow rate, temperature, humidity) for large power transformers. It eliminates manual maintenance through active silica gel regeneration and delivers real-time insulation condition analytics.

Our wave trap surgically remove specific interference frequencies (e.g., 50/60Hz hum, RF noise). Featuring high Q factor and steep attenuation, they eliminate unwanted signals while protecting adjacent frequencies—boosting SNR, dynamic range, and system reliability in audio processing, RF design, and test & measurement applications.