Product Details

Current-limiting reactor

A current-limiting reactor is connected in series with the power system. Its purpose is to reduce the short-circuit current resulting from factory expansion and increased power supply

Key words:

Current-limiting reactor

Category:

E-mail:

Details

Current Limiting Reactor (CLR)

Rated Voltage: Up to 500 kV

Core Function

Connected in series with power systems to:

1.Limit short-circuit currents from grid expansions to levels manageable by existing equipment

2.Protect critical assets: Transformers, switchgear, and cables

3.Reduce fault duration: Enables selective coordination of protection relays

4.Minimize voltage sag: Maintains >85% voltage during faults

Operating Conditions

| Parameter | Standard Specification | Customization Options |

| Installation | Indoor/Outdoor | Arctic (-60℃)/Desert (+70℃) |

| Ambient Temp | -40℃ to +50℃ | Extended range: -50℃ to +60℃ |

| Altitude | ≤3000 m | 5000 m (with derating) |

| Max Wind Speed | 45 m/s (162 km/h) | Hurricane-proof: 60 m/s |

| Humidity | ≤90% (non-condensing) | Tropicalized (>95% RH) |

| Seismic | Horizontal: 0.30g Vertical: 0.15g | High-seismic: 0.5g (IEEE 693) |

| Pollution | IEC 60815 Class III | Class IV (heavy industrial) |

Indoor Requirements:

Ventilation: Forced-air (AF) or Natural (AN)

Air Quality:

Dust: ≤0.3 mg/m³ (non-conductive)

Gases: SO₂ ≤0.1 ppm, H₂S ≤0.01 ppm (IEC 60721-3-3)

Technical Parameters:

| Parameter | Standard Range | Precision Options |

| Rated Frequency | 50/60 Hz | 16.7 Hz (railway) |

| System Voltage | 66-500 kV | 550 kV (BIL 2100 kV) |

| Rated Current | 1-6 kA | 10 kA (forced-cooled) |

| Short-Time Current | 40 kA/1s or 25 kA/3s | 63 kA/1s (peak) |

| Reactance Tolerance | ±10% | ±5% precision grade |

| Insulation Type | Epoxy-resin (dry-type) | Oil-immersed (ONAN) |

| Insulation Class | Class F (155°C) | Class H (180°C) |

| Rated Losses | ≤0.4% of rated power | Ultra-low loss: ≤0.25% |

| Avg. Temp Rise | 80K (winding) | — |

| Hot Spot Rise | 95K (winding) | Fiber-optic monitoring |

| Sound Level | ≤75 dB(A) @ 1m | Silenced: ≤65 dB(A) |

| Terminal Orientation | Axial/Radial | Custom busbar angles |

DKNC Custom Engineering:

Voltage Optimization: ±10% tap changers

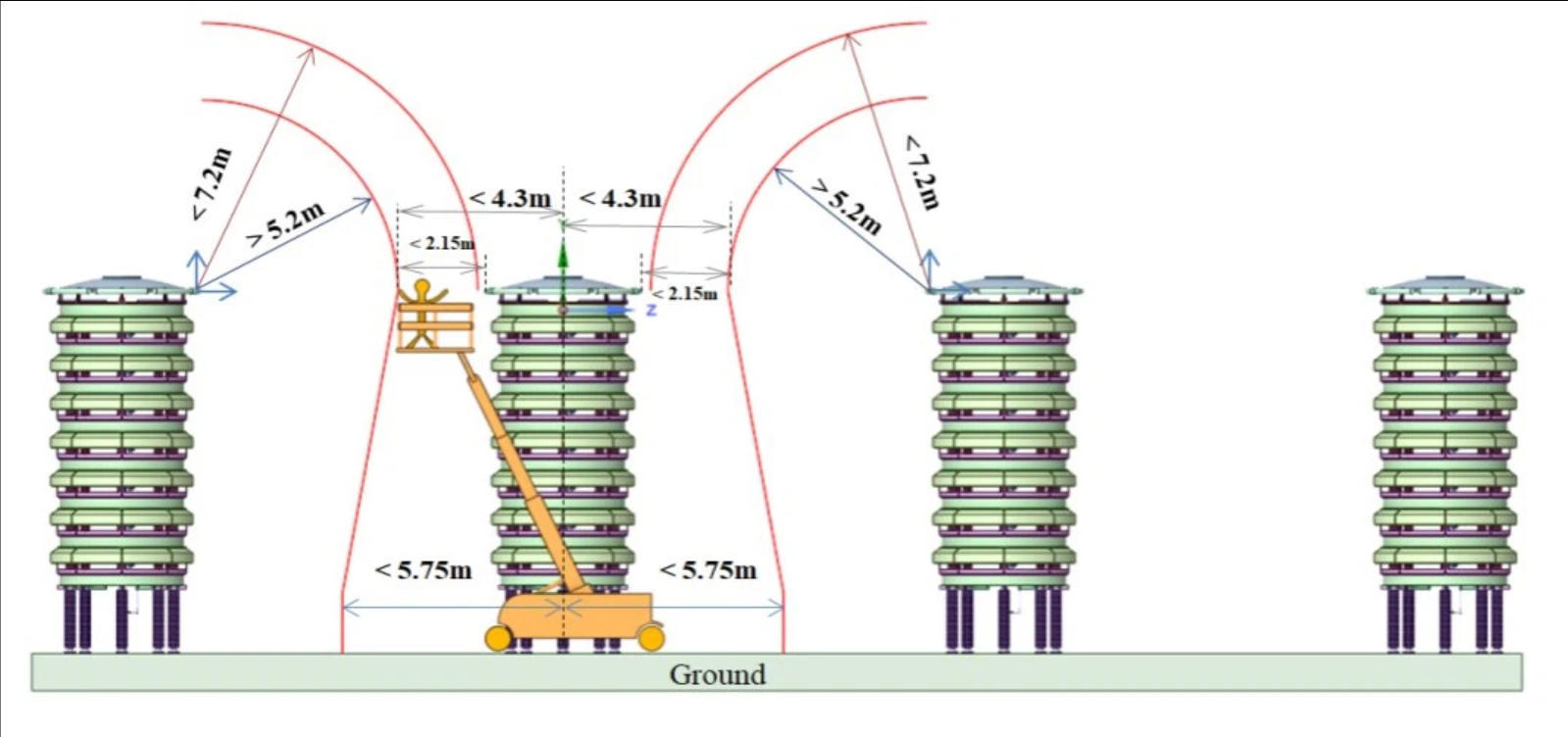

Modular Design: Stackable units for space constraints

Smart Monitoring: IoT-enabled thermal/current sensors

Retrofit Kits: For legacy switchgear (ANSI/IEEE C37)

Send Inquiry

We will contact you within one working day. Please pay attention to your email.

Related Solutions

A novel parallel reactor is connected to the power system in a parallel configuration to compensate for capacitive reactive power in the transmission and distribution system.

Intelligent Transformer Breather( ITB)

An IoT-enabled transformer accessory dedicated to digitalized monitoring of respiration metrics (flow rate, temperature, humidity) for large power transformers. It eliminates manual maintenance through active silica gel regeneration and delivers real-time insulation condition analytics.

Our wave trap surgically remove specific interference frequencies (e.g., 50/60Hz hum, RF noise). Featuring high Q factor and steep attenuation, they eliminate unwanted signals while protecting adjacent frequencies—boosting SNR, dynamic range, and system reliability in audio processing, RF design, and test & measurement applications.