Product Details

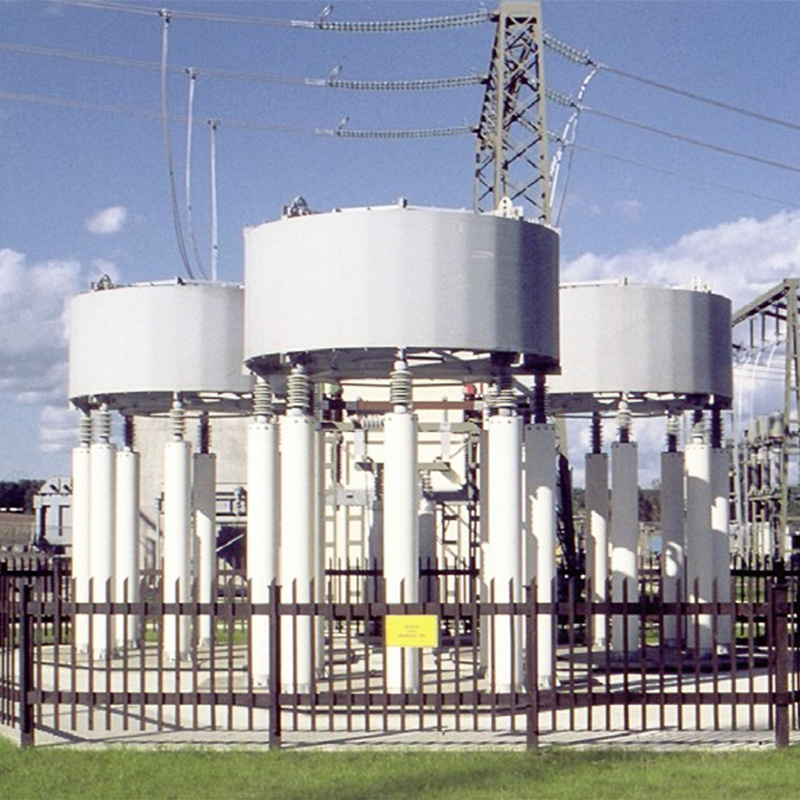

Shunt reactor

Shunt reactors are connected in parallel with the power system. Shunt reactors compensate for capacitive VARs present on lightly loaded transmission lines or underground cables.

Key words:

Shunt reactor

Category:

E-mail:

Details

Shunt Reactor

Rated Voltage: Up to 500 kV

Functional Overview

Connected in parallel to power systems to:

1.Compensate capacitive VARs on lightly loaded transmission lines/underground cables

2.Maintain voltage stability within ±2% of nominal during load variations

3.Improve system efficiency by reducing dielectric losses (up to 30% energy savings)

4.Prevent overvoltage conditions during load rejection or Ferranti effect scenarios

Operating Conditions:

| Parameter | Standard Specification | Customization Options |

|---|---|---|

| Installation | Indoor/Outdoor | Coastal/desert hardening |

| Ambient Temp | -40℃ to +50℃ | -50℃ to +60℃ (arctic/desert) |

| Altitude | ≤3000 m | Up to 5000 m (with derating) |

| Max Wind Speed | 45 m/s (162 km/h) | 60 m/s (216 km/h) hurricane-proof |

| Humidity | ≤90% (non-condensing) | Tropicalized design (>95% RH) |

| Seismic | Horizontal: 0.30g Vertical: 0.15g | Zone 4 seismic (0.5g) per IEEE 693 |

| Pollution Level | IEC 60815 Class III | Class IV (heavy industrial) |

Indoor Requirements:

Ventilation Types: ONAN (Oil Natural Air Natural), ONAF (Oil Natural Air Forced)

Clean Environment:

Particulate matter: ≤0.2 mg/m³

Corrosive gases: SO₂ ≤ 0.1 ppm, H₂S ≤ 0.01 ppm (IEC 60721-3-3)

Technical Parameters:

| Parameter | Standard Range | Precision Options |

|---|---|---|

| Rated Frequency | 50/60 Hz | 16.7 Hz (railway systems) |

| System Voltage | 132-500 kV | 550 kV (BIL 2100 kV) |

| Rated Voltage | 90-105% system voltage | Adjustable taps (±10%) |

| Single-Phase kVAR | 10-150 MVAr | 300 MVAr (custom designs) |

| Max Continuous Voltage | 110% rated voltage | 115% (2 hr capability) |

| Rated Reactance | ±5% tolerance | ±2% precision grade |

| Insulation Type | Mineral oil / Synthetic ester | SF₆ gas / Dry-type (AN/AF) |

| Insulation Class | Class A (105°C) | Class F (155°C) available |

| Rated Losses | ≤0.15% of rated power | Ultra-low loss design (<0.1%) |

| Avg. Temp Rise | 55K (oil), 65K (winding) | — |

| Hot Spot Rise | 65K (oil), 75K (winding) | Fiber-optic monitoring |

| Sound Level | ≤70 dB(A) @ 1m | Silenced: ≤60 dB(A) |

| Terminal Orientation | Top/Side entry | 360° configurable flanges |

DKNC Provides:

1.Altitude Derating: 0.5% capacity reduction per 100m >1000m

2.Seismic Upgrades: Base isolation systems (0.6g capability)

3.Extreme Environments: Sand/dust protection (IP56), anti-icing systems

4.Smart Monitoring: IoT integration for predictive maintenance

Send Inquiry

We will contact you within one working day. Please pay attention to your email.

Related Solutions

A novel parallel reactor is connected to the power system in a parallel configuration to compensate for capacitive reactive power in the transmission and distribution system.

Intelligent Transformer Breather( ITB)

An IoT-enabled transformer accessory dedicated to digitalized monitoring of respiration metrics (flow rate, temperature, humidity) for large power transformers. It eliminates manual maintenance through active silica gel regeneration and delivers real-time insulation condition analytics.

Our wave trap surgically remove specific interference frequencies (e.g., 50/60Hz hum, RF noise). Featuring high Q factor and steep attenuation, they eliminate unwanted signals while protecting adjacent frequencies—boosting SNR, dynamic range, and system reliability in audio processing, RF design, and test & measurement applications.